Comprehensive Disposal Scheme of Drilling Waste Mud

Release time:2021-02-05 18:00 Popularity:

A large amount of waste drilling mud will be produced during the exploration and exploitation of oil, natural gas, shale gas, coal bed gas, geothermal and other energy sources. With the increase of exploration and exploitation, the production of waste drilling mud is increasing. At the same time, the national requirements for environmental protection are increasingly strict. The treatment of waste drilling mud (clean production) has become an indispensable part of the drilling production process. Drilling waste mud can be divided into water-based mud and oil-based mud according to mud types. Drilling waste treatment system is also known as mud non landing system, cuttings non landing system and mud while drilling non landing treatment system. Craun can provide mud while drilling non landing treatment scheme and comprehensive treatment station for various drilling waste mud treatment Plan.

Water-based Waste Drilling Mud Treatment

Water based drilling waste mud treatment equipment (water-based mud non landing system), the main equipment: shale shaker, drilling filter press, automatic dosing system, waste rock cuttings collection and feeding system, emergency mud tank and other equipment. The water content of mud cake is less than or equal to 45% after being treated by water-based drilling waste mud treatment equipment (water-based mud non landing system), which can meet the requirements of road transportation. The waste water can be treated by water treatment equipment and discharged up to the standard.

Customized system welcome to inquire at 86-29-89054256

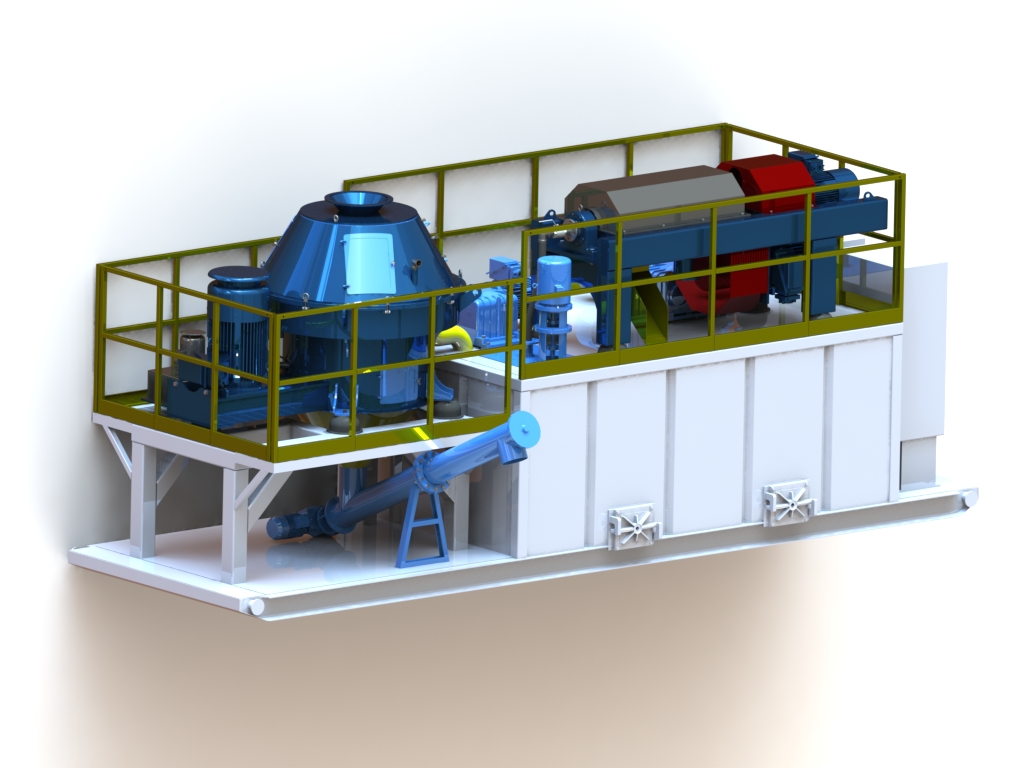

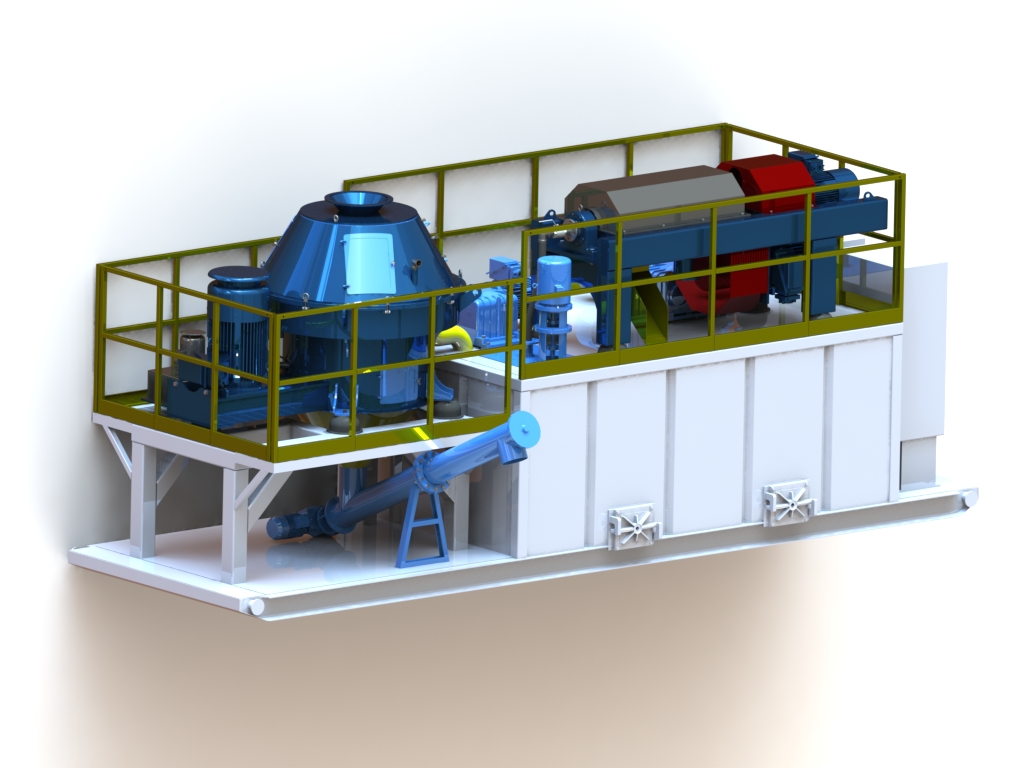

Oil-based Waste Drilling Mud Treatment

Oil based drilling waste mud treatment equipment (oil-based mud non landing system), the main equipment is: drilling fluid high-speed centrifuge, drilling cuttings dryer, waste cuttings collection and feeding system, emergency mud tank and other equipment. The qualified mud in drilling cuttings can be effectively recovered after being treated by oil-based drilling waste mud treatment equipment. The oil content of the dried drilling cuttings is less than or equal to 10%. The qualified mud is recycled to the drilling solid control system, which greatly saves the cost of mud use and reduces the outward transportation of cuttings.

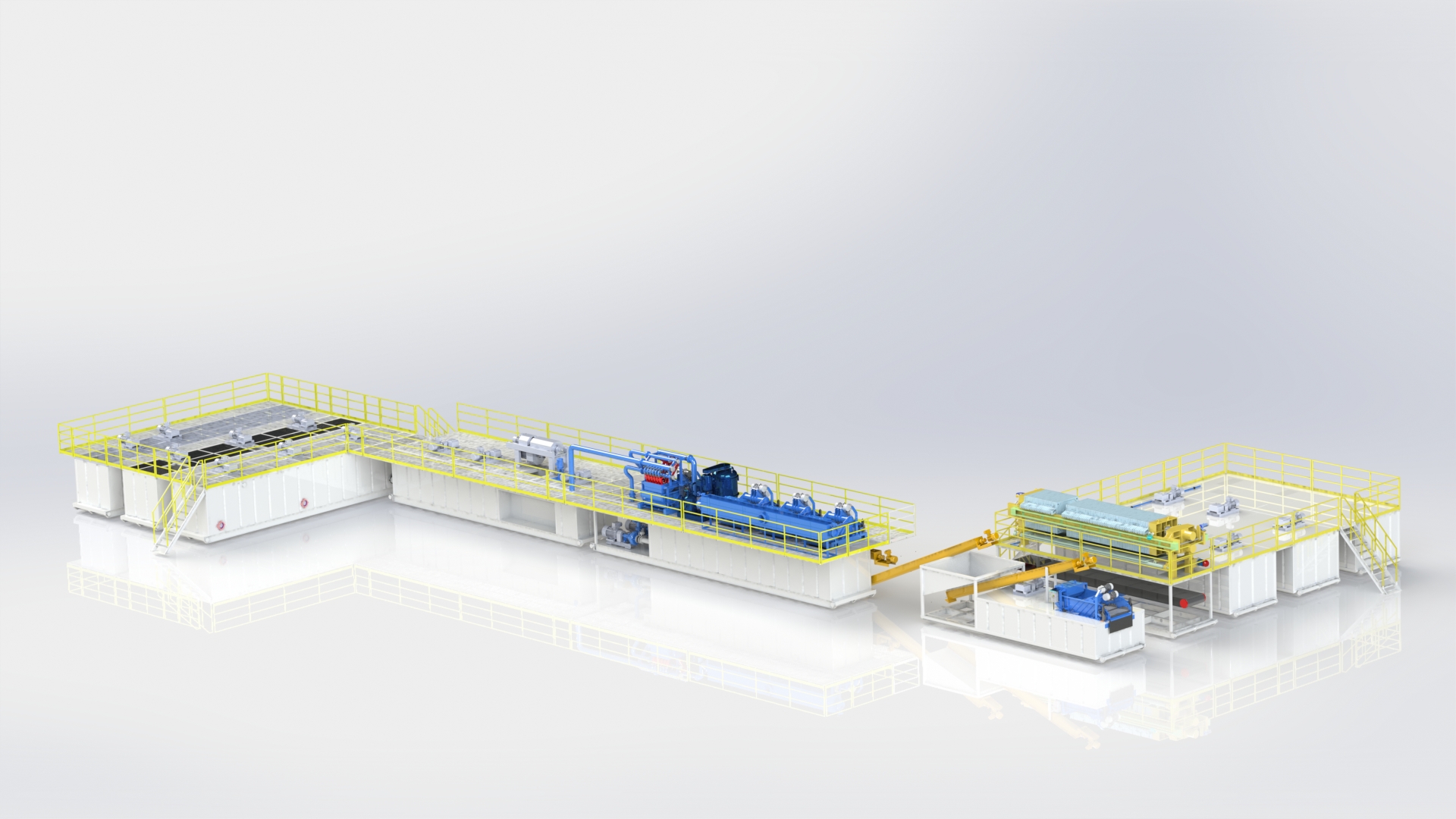

Comprehensive Disposal Scheme of Waste Mud

Compared with the treatment scheme of waste drilling fluid while drilling, winter construction is difficult, which cannot meet the resource utilization and discharge standard. The comprehensive disposal mode can make full use of the existing water, electricity, road, information and other systems, determine the treatment capacity according to the geological development plan and the actual growth of waste well fluid, and reasonably plan the treatment unit. To achieve the purpose of secondary utilization of mud, standard discharge of waste and deep utilization of resources.

The mud comprehensive treatment station can comprehensively treat the fracturing reverse drainage fluid and drilling waste mud. By controlling the solid phase of the mud and reusing it after secondary preparation, the discharged dry slag can be paved or the planting soil can be reused, such as centralized brick making process, solidified particle paving, biodegradable fertilizer, etc. The wastewater was filtered step by step to meet the discharge standard.