Release time:2021-02-03 14:49 Popularity:

1. Purifying the mud completely, effectively controlling the mud performance index effectively, reducing the sticking accident, and improving the quality of hole making.

2. Realizing mud recycling & saving mud making materials, reducing the cost of waste pulp transportation and pulp making cost greatly.

3. Adopting the double deck screen system design which has the better purification effects than single deck screen. Easy operation & maintenance.

4. Mud recycling reuse reduce the impacts to the environment and save the cost.

5. The system design can run continuously and improve the construction efficiency.

6. The system adopts modular design, small footprint, and easy to remove and maintain.

|

Model |

Capacity |

Particle Size |

Sieving Capacity |

Power |

Inlet Dia |

Outlet Dia |

Weight (t) |

Dimension |

|

|

gpm |

(m³/h) |

||||||||

|

GLSP50 |

220 |

50 |

45 |

5-15 |

12.5 |

DN65 |

DN100 |

2 |

2050×1720×2200 |

|

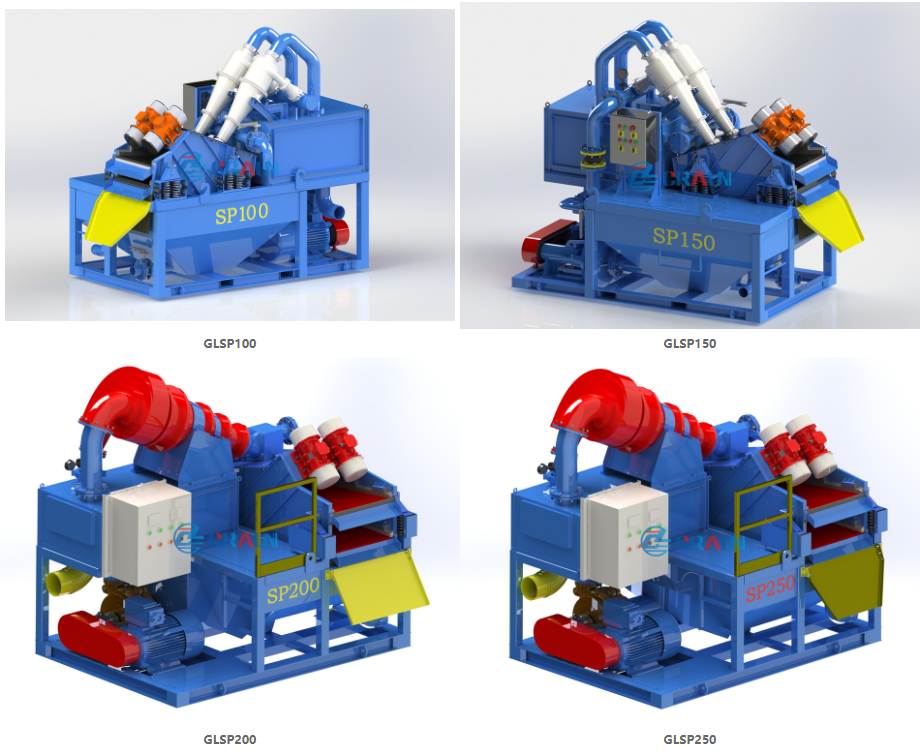

GLSP100 |

440 |

100 |

60 |

20-50 |

24 |

DN100 |

DN150 |

2.8 |

2850×1700×2400 |

| GLSP150 | 660 | 150 | 60 | 20-50 | 32 | DN100 | DN150 | 3.2 | 2860×1720×2400 |

|

GLSP200 |

880 |

200 |

60/30 |

30-80 |

48 |

DN150 |

DN250 |

5 |

4550×2200×2900 |

|

GLSP250 |

1100 |

250 |

58 |

DN150 |

DN250 |

5.7 |

4580×2300×2900 |

||

|

GLSP500A |

2201 |

500 |

60 |

80-250 |

120 |

DN300 |

DN250 |

21 |

11350×4250×6500 |

| GLSP500B | 2201 | 500 | 30 | 100-300 | 124 | DN300 | DN250 | 18 | 7150×3550×5500 |

Screen capture, wechat identification QR code