Release time:2021-02-03 14:48 Popularity:

Waste drilling fluid (water-based) is the main waste produced in the process of drilling. It is a multiphase stable suspension composed of clay, weighting materials, drilling cuttings, inorganic salts and other components. With the deepening of oilfield development, the production of waste drilling fluid is increasing, and the environmental contradiction caused by waste drilling fluid is becoming more and more prominent. With the increasingly stringent requirements of environmental protection in our country, it is an inevitable trend that the disposal of waste drilling fluid without falling to the ground can meet the HSE site specification and transportation conditions.

Crauntec follows the design concept of safety, reliability, advancement and economy to provide comprehensive treatment scheme for water-based drilling waste while drilling and station construction.

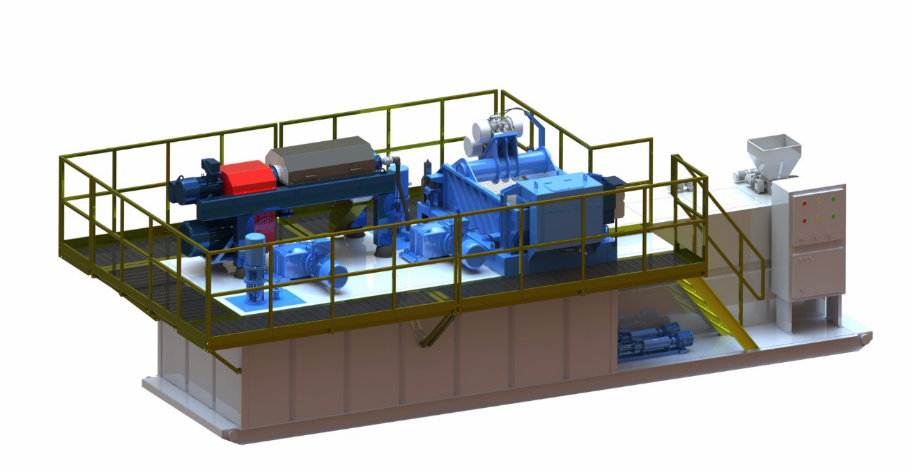

Treatment while drilling (Plan 1)

The system consists of screw conveyor, high frequency drying shaker , high-speed dewatering centrifuge, tank and conveying system. According to the different mud media, it can be used for the treatment of water-based mud and composite base mud. The cuttings over 5mm are screened by high frequency shale shaker, and the mud less than 5mm enters high-speed dewatering centrifuge for solid-liquid separation. The separated mud can be reused in drilling solid control system. The whole production process does not add any chemical additives and will not damage the mud composition.

Treatment while drilling (Plan 2)

The system is mainly composed of high frequency drying shale shaker, diaphragm filter press, dosing device, flocculation tank and storage tank. It is mainly used for non-landing and tail slurry treatment of water-based mud with high viscosity. Its advantages are good dehydration effect, low water content of solid phase, but its disadvantages are not continuous operation and large occupation area.

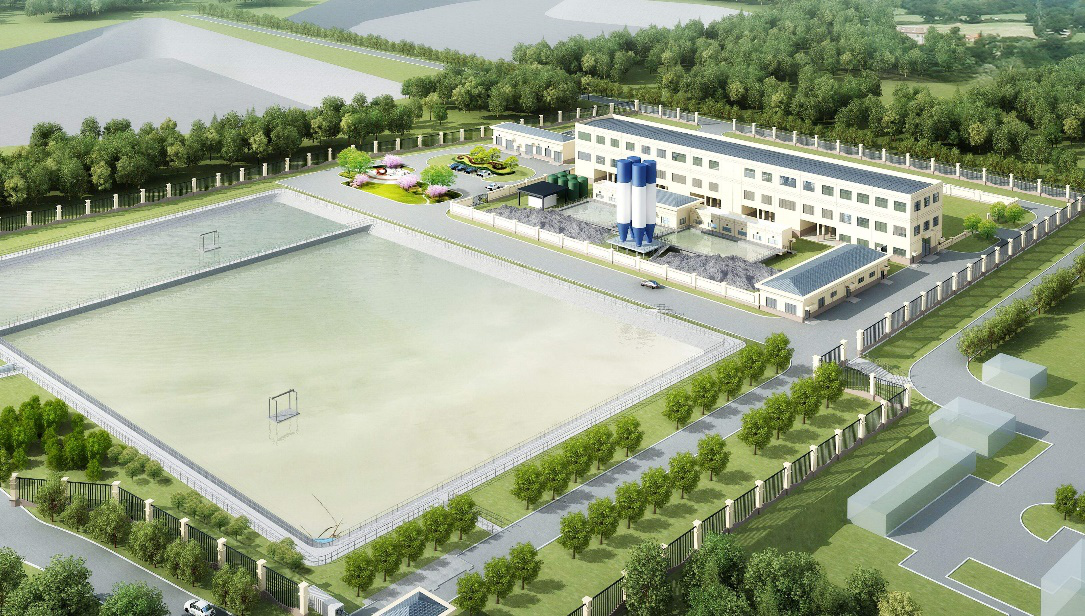

Comprehensive Drilling Waste Management

Compared with the treatment scheme of waste drilling fluid while drilling, winter construction is difficult, which cannot meet the resource utilization and discharge standard. The comprehensive disposal mode of the plant can make full use of the existing water, electricity, road, information and other systems, and determine the treatment capacity according to the geological development plan and the actual growth of the waste drilling fluid, and reasonably plan the treatment unit. To achieve the purpose of secondary utilization of mud, standard discharge of waste and deep utilization of resources.

The mud comprehensive treatment station can comprehensively treat the fracturing reverse drainage fluid and drilling waste mud. By controlling the solid phase of the mud and reusing after secondary preparation, it can pave the road for the discharged dry slag or reuse the planting soil, and filter the wastewater step by step to meet the discharge standard.

Related videos:

|

Model |

Capacity |

Treatment Method |

Treatment Process |

Mud Reuse |

Moisture Content |

Mud Cake |

Wastewater Treatment |

|

GLST-50 |

≤50m3/h |

Centrifugal type while drilling |

High frequency screening |

Yes |

≤80% |

Transportation, incineration and landfill |

Solid Control Reuse |

|

GLST-60 |

≤60m3/h |

Filter press type while drilling |

No |

≤60% |

Laying of well access road |

Water treatment plant |

|

|

GLJZ-500 |

500 m3/h |

Centralized station construction |

Screening, Chemical destabilization |

Yes |

≤60% |

Planting soil, making bricks |

Up to standard emission |

|

GLJZ-800 |

800 m3/h |

≤60% | |||||

|

GLJZ-1000 |

1000 m3/h |

≤60% |

Related videos:

No video yet

Screen capture, wechat identification QR code